Fabric Inspection Machines

Fabric Inspection Machines

Fabric Inspection Machines are designed to check defects and shade variations in fabrics. Our upgraded version of the Fabric inspection machine is robust with many upgraded features.

- The edge guiding system provides uniform winding

- Imported rubber fillets to provide perfect tension on fabrics

- Selvedge guided (shifting) winding option for perfect winding to manage proper selvedge edge of the fabric (avoid bulky roll & curling from both the edges of the fabric)

- Auto doffing / Weighing system options provided as per customer's requirement

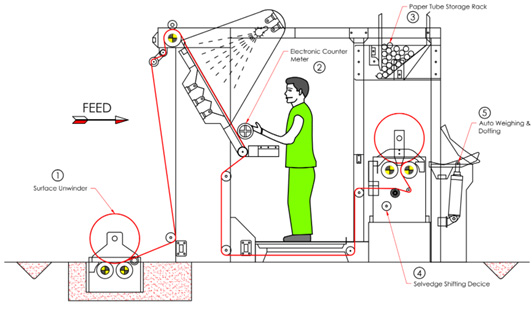

- 1. Surface Unwinder

- 2. Electronic Counter Meter

- 3. Paper Tube Storage Rack

- 4. Selvedge guided (shifting) winding option

- 5. Auto Doffing and Weighing system

- Robust and attractive design.

- Inspection table is laminated with adequate number of tube lights provided underneath and overhead the glass with variable lighting arrangement.

- Push button controls are given in the centre as well as on both the ends of the inspection table.

- Fabric runs face in/face out.

- 2AC Motors are synchronized using variable speed ac drives

- Cloth can run in FORWARD as well as in REVERSE direction instantaneously.

- Jogging or inching as standard is provided to stop the machine at the right location of the defect

- Soft start and instantaneous stoppage of fabric.

- Automatic stop arrangements to stop the machine at the end of the fabric piece.

- Bow bar has been provided in the batching device to open out the creases in the fabric.

- Edge Control arrangement is provided for uniform winding arrangement.

- Perfect tension during the flow of the fabric is provided using dancing roll assembly.

- Mechanical Meter Counter is installed in front on platform top for easy reading.

- Roll to Roll, Roll to Plaiting, A-Frame to Roll, Loose/Plaiting to Roll, Roll to Roll with Plaiting arrangements can be supplied.

- Machine speed is variable 0-35 meters per minute positively & infinitely variable.

- Power requirements vary from 3 H.P. depending upon the requirement.

- Geared Motor of Bonfigliole / Rotomak makes are used.

- Machines are manufactured for 60” - 213” fabric width sizes.

Samsa was a travelling salesman - and above it there hung a picture that he had recently cut out of an illustrated magazine and housed in a nice, gilded frame. It showed a lady fitted out with a fur hat and fur boa who sat upright, raising a heavy fur muff that covered the whole of her lower arm towards the viewer. Gregor then turned to look out the window at the dull weather.

waved about helplessly as he looked. "What's happened to me?" he thought. It wasn't a dream. His room, a proper human room although a little too small, lay peacefully between its four familiar walls